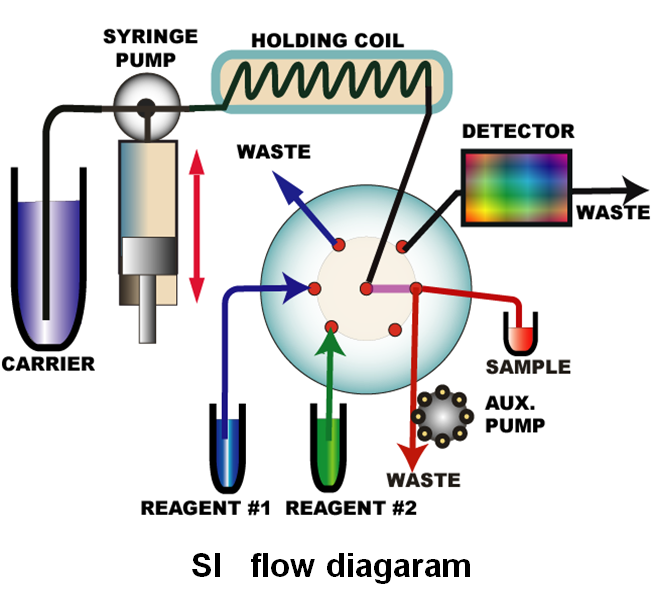

The multiposition valve is the hub of a Sequential Injection solution processing system. Its central port is connected to a high precision stepper motor driven syringe pump that is used to aspirate well-defined volumes of sample and reagent solutions into the holding coil. The stacked zones are moved forward through the valve and into the detector by flow reversal for monitoring of the reaction product.

All functions of the system - flow rates, aspirated and delivered volumes, valve positions and data collection – are computer controlled and programmable from a keyboard.

Sequential Injection System

2.1.4.

In contrast to FI, Sequential injection is not based on continuous flow, and therefore consumes reagents and produces waste only, when a sample is being processed. There are two principal configurations of SI instruments. The conventional SI setup, shown here with external detectors and external peripherals and microSI system that employs the Lab-on-valve® platform where all components (flow cells, micro columns and detectors) are integrated within a microfluidic manifold mounted atop the multiposition valve.

The conventional SI instruments are marketed by Global FIA under the trade name Zone Fluidics. Micro SI systems with lab-on-valve are marketed by FIAlab. For more details consult 2.5.2.